The MicroURANUS Project headed by Professor Il Soon Hwang of Ulsan National Institute of Science and Technology in Ulsan, Republic of Korea has developed a new small modular reactor which can power maritime vessels and requires no refueling during its 40-year lifespan. These SMRs have intrinsic safety and safeguards characteristics, as well as being environmentally friendly even in the event of an accident.

Professor Il Soon Hwang, 17 November 2021

International maritime shipping accounts for 90% of the world trade volume. Currently, maritime systems including ships and plants produce up to 3% of worldwide greenhouse gases (GHG). At its latest meeting, the Marine Environment Protection Committee of the International Maritime Organization (IMO) has decided to reduce by 2050 70% of GHG from the 2008 emission level. The European Union aims to go beyond the IMO target.

Diesel fuel costs of international shipping amount to about one half of the lifetime operational expenses. Moving from diesel to natural gas adds to costs but does not lead to much reduction of GHG, owing to fuel gas leakage through engines by a process called methane slip. A more effective solution can be green hydrogen which can be used to generate electricity.

Maritime experts point to nuclear power as the ultimate solution for making zero-emission shipping inexpensive. Small modular reactors (SMRs) have been widely used in naval submarines and ships for more than 60 years. Although SMRs are much safer than their larger counterparts, the maritime environment is too harsh to ignore safety concerns.

Owing to the International Atomic Energy Agency (IAEA) restrictions on uranium enrichment to a maximum of 20 percent, civilian SMRs can only use nuclear fuels with uranium enrichment of not more than 20 percent. For this reason, water-cooled SMRs require multiple refuelings during their typical design life of about 40 years. There have been nuclear explosions during the refueling of nuclear submarines on water because of uncontrolled reactor motions, which have led to major radioactive fallout in the neighboring areas.

To eliminate the need for a maritime vessel having to refuel its civilian SMRs using low-enriched uranium, the MicroURANUS Project at the Ulsan National Institute of Science and Technology (UNIST) in the Republic of Korea has developed MicroURANUS, a fast neutron reactor which generates 20 MWe and permits a nuclear-powered merchant ship to use its initial charge of nuclear fuel throughout its 40-year lifespan. A pair of MicroURANUS microreactors can power one of the largest containerships without emitting any GHG throughout their lifetime.

The reactor core of MicroURANUS consists of uranium dioxide fuel and a heavy liquid metal coolant called lead-bismuth eutectic. This coolant, however, is also notorious for producing highly toxic polonium radioisotopes under neutron bombardment. Crews on board can relax, as the rugged MicroURANUS reactor vessel is hermetically sealed after the first fuel loading, giving polonium no chance to escape. If the ship sinks in an accident, the liquid metal will be frozen when seawater touches the outer wall of the leak-tight reactor vessel, locking all the radioactivity inside and resisting high pressures underwater.

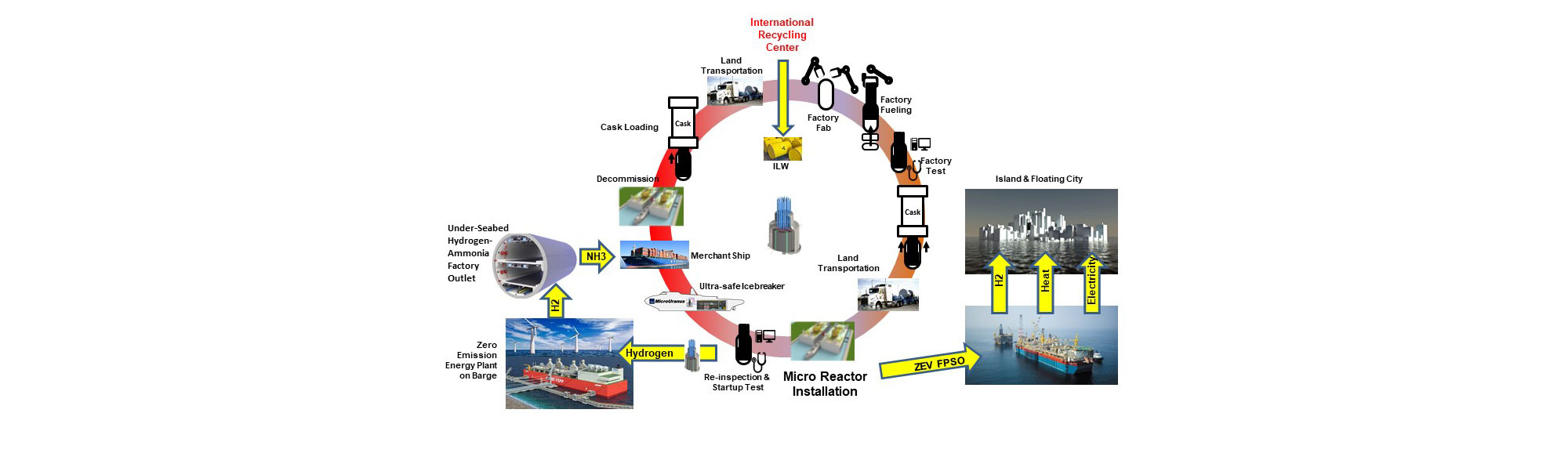

MicroURANUS will completely overhaul the nuclear power business. It will implement the so-called “Cradle-to-Grave” approach that has been called for by global leaders including the IAEA’s former Director General Mohammed El Baradei, former President of United States George W. Bush, and President of the Russian Federation Vladimir Putin. As with jet engine production and its quality assurance procedures, the completed MicroURANUS will be factory-tested up to sufficient stress levels by neutron bombardment, as depicted in the schematic above. After completing the factory test, the mildly radioactive MicroURANUS will be transported by using a heavily-shielded cask to a dry dock at a shipyard for installation into the engine compartment of a barge or a ship. The second qualification test will be carried out on board on the dry dock. Then a sea trial will be made prior to the commissioning for its 40-year-long journey. Safety check-ups and safeguards inspections of the reactor and the maritime system will take place in accordance with both domestic and international regulations. To minimize maintenance needs, MicroURANUS design avoids all rotating machines, by replacing them with innovative static mechanisms, such as electromagnetic pumps for coolant circulation.

At the end of its life, the microreactor will be turned off and frozen cold before being removed, inserted into the heavily-shielded shipping cask and transported to an international refueling center, as depicted in the schematic. Nuclear waste from the reactor will be minimized by recycling the spent fuel, coolant and other materials, making the whole system sustainable and environmentally acceptable. Its safety is far superior to any other SMR, thanks to the chemical inertness and high boiling point of the lead-bismuth eutectic coolant. By design, the possibility of a meltdown accident is practically eliminated and no crew evacuation will be needed even in the hypothetical worst-case accident, owing to adequate safety margins in the defense-in-depth design of the microreactor, which keeps all the radioactivity within the nuclear engine compartment. Creating a sufficiently long safety record required for installation in an operating maritime vessel will take more than a decade.

The service life of the microreactor can also make the IAEA’s safeguards task easier, as there is no chance to remove any fuel materials from the reactor, which is hermetically sealed. This also assures nuclear safety and security against pirates or terrorists. The initial application of the microreactors will be for the generation of electricity and heat on barges off the coast, so that emission-free hydrogen can be produced from seawater at low cost. It is hoped that the operation records of these offshore hydrogen plants will provide the IMO with an adequate database to update its safety code and convince seaports to accept MicroURANUS-powered ships.

More details about MicroURANUS may be found in the IAEA’s SMR publication available on the web at https://aris.iaea.org/Publications/SMR_Book_2020.pdf that also provides valuable information about non-water-cooled microreactor designs that run for life without refueling. The MicroURANUS project (NRF-2019M2D1A1067205) has been supported by the National Research Foundation of the Republic of Korea since 2019.

Picture: MicroURANUS for Hydrogen Production and Ship Propulsion with Sustainable Life-cycle © UNIST

Other Articles Which Might Interest You

Professor Hwang Il Soon’s Model for Unlimited and Safe Nuclear Energy: Small Modular Reactors and Multinational Fuel Cycle Centers